I'm just gonna stick to slotted, thanks

Fun fact: Torx screwdrivers are compatible with Torx Plus screws, but Trox Plus screwdrivers are only compatible with Torx screws that are one size larger

Fun fact: Torx screwdrivers are compatible with Torx Plus screws, but Trox Plus screwdrivers are only compatible with Torx screws that are one size larger

I repair a lot of tech and I have never seen torx other than the standard, and security version. And security torx drivers are compatible with regular torx

There's other types on cars

Torx plus is getting more common and you can use a torx bit on them still, and superior to torx IMO. I bet you’ve seen since but didn’t notice the difference. As a machine designer it’s my preference but I don’t often for cost

Torx plus ultra premium pro

I assume all those are proprietary temper resistant, tool for it will be expensive so not many tool shop gonna have it.

Not really. A solid set for security Torx is available for like $20 from reputable brands. Naturally, you can get higher quality sets and sets that add other security bits, but you still won't land in an unacceptable price range even for private use, let alone a pro shop.

Use torx all the time on not only building sites, but in machinery repair too.

There's only one type of torx and I think OP is winding us up :)

Edit - ha ha oh my fucking god. So it turns out the patent for torx expired in 1990. No change for us in Europe, we're still mostly using the original design.

Not so much for the yanks. Textron, the original patent holder, realised it'd be faaaar more profitable to "licence" slightly improved designs and try to phase out the original

Enjoy your torx my euro friends, and have a giggle at the seppos paying for a fucking screw head lol

Greed to the point of mental illness 😂

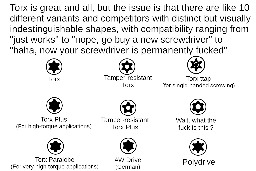

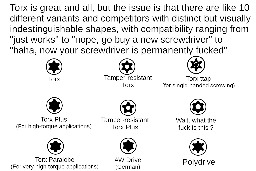

There isn't. There's Torx, Torx Plus, and Torx Paralobe. See here for more details: https://www.semblex.com/en/pdf-files/technology-files/torx-paralobe-pdf/ . Plus there's also the ttap and tamper-resistant variants shown in the meme.

As other people have mentioned, Torx screwdrivers are forwards compatible with Torx Plus and Torx Paralobe. But the screwdrivers for the newer standards are not backwards compatible with older screws.

Similarly, Tamper-Resistant Torx screwdrivers can be used on regular Torx screws. But Tamper-Resistant Torx Plus screwdrivers cannot be used on regular Torx Plus screws -- it's a completely different shape!

If you're in a professional setting where you order high-quality screws and drivers in bulk directly from a manufacturer, I'd imagine that this isn't much of an issue. But if you're a hobbyist or just need to repair something in a domestic setting, the three different torx variants plus the other non-torx hexalobular screws (WA drive, Polydrive, T-Star Plus) can cause quite a bit of confusion. Anecdotally, I have a set of what I thought were really low-quality Torx bits. Turns out, they're actually good-quality Torx Plus bits that by design don't fit my Torx screws.

Yeah that's just what Big Torx wants us to think man

Put timing chains on a Ford v6 without a torx plus 55 and let us know how that went.

Security torx is actually very weak. If you don't have the security bit, you can break it with a flat head and turn it into a normal torx.

Torx are superior to all other types. I've been a carpenter for roughly three decades, and have suffered through all manner of fastening methods that have come and gone. None of them can hold a candle to Torx. I've never seen another type that can resist stripping out so well and for so long.

How do you feel about square drive? I'm no carpenter, just someone that's done enough work around the house, but I've found that Torx are the best option but square is a close second (but I don't think I've used them in any especially high torque situations, and they may fall short there).

Square drive (or Robertson) I consider a close second. They do tend to strip out faster, especially in "softer" fasteners like stainless steel.

Square and Robertson are different. No taper in square

So square is a close second in terms of quality, while being vastly simpler and cheaper to manufacture. Seems to me like i'd prefer square.

Also i'd be terrified of getting dirt in a torx screw, good luck cleaning it to make it usable again. Though i haven't actually had this problem personally so it's just a hunch

You clearly have no idea how fasteners are manufactured... and you worry needlessly about hypotheticals.

I have torx all over my mountain bike that gets caked in dirt, a little bit of water and a pick gets them usable in seconds. I could argue that hex is superior to square but they're both worse than torx so who really cares.

Torx, hex, and square/Robertson all require broaching, generally with a rotary broach. The manufacturing process is basically identical, though the manufacturing of the machine tools varies slightly.

Torx should be the default over Phillips for sure. Phillips is fine for shit like access panels or screw terminals. Slotted is useless for anything but the adjustment on pots and thermostats. Robertson is just a proto-torx. Everything else either exists to make someone money or is a bolt

Robertson drive tho

robertsons are tapered, so unless you get a proper positive lock, or they have dirt in them or something, they're more liable to stripping out. But other than that, they're great.

Least favorite for sure.

Vastly Superior to Philips, which is vastly superior to blade/slotted for anything resembling a power tool.

Fellow contractor here. Torx or go home. Drywall screws are the only exception I'm willing to make.

Where do you buy torx wood screws or torx metal screws?

I've never seen any.

Most screws sold around here have a torx head

IIRC Spax and GRK make torx multi-purpose fasteners that you can use for wood and metal

And a set of Allen keys usually saves a trip to the hardware store if you're missing the right size Torx bit.

Hexes save trip to store when you need torx? How?

Because a hex key can fit (albeit imperfectly) into a Torx opening and loosen or tighten the fastener as needed.

It's more likely to slip or strip, but it's better than nothing.

The opposite is also true.

Robertson is superior to all.

What about hexes?

Torx can't hold shit. They're single use screws.

We can debate this all day long but we all know torque is cheap.

But enough torque, have at thee!

the worst is not when the screwdriver is fucked but the screw is. That is some huge pain in the ass

Torx doesn't get fucked though, compared to alan or philips

What about square drive… where does it fit in

That’s right, it goes in the square hole.

Robertson! Say his name!

I was saying it in Mercian for our southern neighbours

I'm not american so you wasted it anyways

Fun fact: There are plenty of times a screw that looks like a Philips head is also compatible with a square drive. I've mostly seen this on electrical outlets and Ikea furniture.

I don't know why Robertson/square drives aren't more common. They're stable and they resist stripping and rounding.

You mean Pozidriv?

wait really? I would imagine those small corners would easily get flattened compared to something with deeper ridges like philips

Phillips strips way, way easier than Torx. Stripping generally happens when a screwdriver cams out, or pops out of the screw. Here are some excerpts from Wikipedia of Torx vs Phillips.

And Philips on the other hand:

I'm not sure about Allen. It doesn't cam out very much, but it does still strip a lot easier than Torx. Probably due to the smaller contact points.

Well said.

And with the hex/Allen, it's the small contact points as well as the smaller volume of material that needs to be deformed or removed before slippage can occur, as well as the angle of force on the contact point.

With a hex, the contact point and direction are such that the tool is effectively trying to scrape off material at an angle, and if/when it succeeds even a little bit, it's now much more prone to fail.

With a Torx, the contact area might still be small, but it's being applied to the lobe in a more perpendicular direction, so rather than a scraping failure, it's more of a force that is pushing directly against steel instead of scraping. Not that it can't fail, but the route to failure is significantly less likely.

Yeah, it was made with torque in mind (like, it's in the name lol). For smaller screws using an impact, you can expect to break the screw before you strip the torx on top. And by smaller I don't mean tiny, more like M4, M5

Maybe because different material? Obviously CrV steel won't get fucked like chinesium, no matter the shape.

my brother in christ have you seen phillips head and posi drive?

Life sucks. You can't win.

Working on an 86 RV and hating posi drive. I swear they were designed to strip.

Also no mention of Spider drive that everyone insists is a torx

probably because nobody buys anything other than torx, considering it's a brand name, it's not like they're going to just do the funny and mislabel a screw. Phillips heads are so common it's a lot easier to mistake them.

Though if you're in the field and you run across one i could see it being annoying.

Or Phillips and JIS?

JIS isn't real

Useful tip: with security torx screws, with the little nub in the centre, if you get a small flathead screwdriver to jam in there and wiggle a bit, that centre bit will snap off without much difficulty.

You should be able to use a regular Torx screwdriver bit after that.

This is really gonna come in handy during some of my heists

Their only "heists" when you get caught, until then they're "shenanigans" 😁

It's easier to just pick up security bits at any hardware store...

Yeah, just exclusively buy security bits and stop worrying about it.

One of these is a settings icon

I have to admit that each time I saw a torx security screw on a case I had to open (looking at you, Compaq) this made me so angry that I used to punch the middle pin away with a flathead screwdriver, and replace the screw with a regular one later. This was in those past times I did not have a fuckton of assorted torx bits in a gigantic case...

Didn't Compaq use to have those torx with a slit in them where you could put a flathead screwdriver in the slit part?

I know HP uses those on some computers. Pretty neat design, if you ask me!

Yes I've always referred to them as Compaq screws but mainly because I personally saw them on Compaq first. I think HP bought Compaq at some point and that might explain why they are used on both brands. Don't know which brand started using them first.

I would have rather had they just used Phillips screws but as far as weird screwheads go these aren't too bad.

At least the good thing about them is the threads are standard and they can be replaced with a Phillipshead case screw just as well.

I'm with you. I've replaced all the torx screws on my Dell with Philips head screws because fuck you Dell. (all the screws inside were already Philips)

Lmao you've clearly never met Philips.

And if you're advocating slotted screws (flathead) you've already lost.

Torx is supreme. The end.

No slot shaming!

Robertson is superior.

sell them in the continental US then >:(

There are basically none here in the 50 states. You can find em, along 50x more torx screws...

Hex is supreme, torx is mental health problem

Hex strips itself constantly. Torx never does that.

Robinson aka the square head is by far the superior choice.

LOL sure, good one... Only time that square abomination is the answer is if the question is "what do you get if you put a toddler in charge of designing a poor knockoff unbrako head?"

TEAM TORX REPRESENT!

Things are getting heated in the screw fandom

I'm not canadian, so I don't have a lot of experience with robertson. But from the limited experience that I do have, I would rate it 10/10.

What would you recommend for smaller screws (e.g. for electronics)? As far as I know, there aren't smaller sizes of robertson like there are with torx?

Pozidrive has real nice engagement and doesn't cam out like Phillips does. And JIS drivers do a better job in Phillips than Phillips ones do.

After wrecking some JIS screws on a vintage reciever, I bought a nice Vessel-brand JIS driver set, and use it for all my crosshead needs.

Pozidriv reliably makes me projectile vomit ☹️

I’ve driven tens of thousands of pozidrive 2/3 screws into timber with an impact driver. For whatever reason my experience is the diametric opposite of yours. Big up the Pozidrive massive.

I absolutely love the amount of strong opinions on screw heads 🙏

Me too. Nice to see the passion of the construction industry ( and the weekend warriors too)

It's probably because of the impact driver. The bit seats back into the bottom of the slot between every impact. This doesn't happen with normal drivers.

People (try to) use a drill driver as opposed to an impact driver? Wow. I now understand why they could have a grim experience… thanks.

Yeah but JIS for screws/bolts has been abandoned by the Japanese govt as of... 2005?My JIS screwdrivers are fantastic, not easy to torque out on a regular Phillips screw. Stick with the "vessel" brand.

E: I can't find anything more than discussion about it, nothing official. Sorry for the wrong info, looks like JIS screws are still alive.

I did not know that, but yes to Vessel!

I think I was wrong, see edit. Carry on!

Philips doesn't cam out that easily either. Most people just don't realize there's three common sizes.

I mean...that's an inherently subjective statement.

But more objectively, regardless of how easily, it's still the worst of the available options.

Found the Canadian.

Its flaw is that you can only get to it in 90deg increments. When the screw is in a hard to reach place that will drive you crazy

As a person that changes out a lot of electrical outlets and switches I have to agree.

Relevant xkcd

Relevant xkcd

Don't discount hex, paired with a ball-end wrench, those are great for odd angles or tight spaces a straight wrench can't get too.

they're pretty good but semi liable to stripping due to lower surface area, as long as you use the right tool, and a quality one, you'll be fine though.

Also hex is somewhat inter-compatible with torx, which is really cursed.

Torx are easier to strip, especially the smaller sizes. They're pretty much single use screws.

small screws in general are just easy to strip. Small torx is also liable to breaking a driver, like most small screws and drivers.

Torx though, i've never had strip out once, even doing construction with them. Phillips on the other hand, they kill screws constantly, and the bits themselves get all chewed up causing all kinds of problems. Torx bits still look fine though.

Torx aren't exactly tapered, so they much less of a problem with stripping, compared to any tapered design, because tapered designs have issues with backing off.

Hexes are very sturdy. I ride mountain bikes and for some reason brake rotors are secured with Torx while all other screws are hexes. Torx on rotors are usually tightened to 4-6Nm and they are single use 99% of the time. At the same time there are plenty of hexes of the same size which are tightened to 8-10Nm and there are zero issues.

Torx are fucking useless. And don't get me started on tiny Torxes in laptops...

you're not using like, soft fasteners or some shit right?

I could see hex performing better on a softer material. That or you're doing something goofy. I'd be surprised if torx were stripping at that low of a torque rating, unless ur using hex drivers on them or something.

Fasteners are standard from rotor manufacturers. I have no clue what they're made out of. But in 30 years of cycling I've never had a single Torx which would last more than one cycle of screw in screw out.

that's bizarre. Torx are commonly used in construction with impact drivers, and in vehicles as well. Very rarely are they ever problematic, and that's with quite significant shock loading as well as torque application in the case of construction, i would imagine more than in a bike, but i wouldn't be able to say off the top of my head, though they might be bigger standard head sizes, so that could be it.

Regardless, begs the question why hex screws aren't in construction, those should be simpler and easier to produce.

I'm Jewish, so I'm going to have to go with the tamper-resistant Torx when I need to use screws on myself.

Edit: A troll flagged this as antisemitic, so apparently I hate my own ethnicity?

Would you mind explaining? I think not being Jewish and not having enough he-bros is making this go over my head.

It’s a Star of David.

https://en.m.wikipedia.org/wiki/Star_of_David

Oh my... Now I feel silly. I was trying to find wordplay and not looking at the image because I'm familiar with Torx variants.

Welcome to the internet

Not a single person sharing the xkcd comic about standards? Well I'm not doing it.

Why is screw DLC legal? Why are people ok with companies preventing people from working in their own devices?

Tamper proof is to prevent random idiots from messing with your stuff.

Random idiots that don't know hardware stores exist

Once they're determined to fuck with your stuff, they're no longer random. It's just to delay the occasional dingleberry with a multi tool until they get distracted and forget.

"Huh, doesnt fit. Oh well, guess I'll carve some folk art into the shitter door."

Then you can just spackle over the swastikas, but you don't usually have to reassemble the privacy panels.

Every lock can be broken. My step grandfather would use tamper proof screws to board up his lake house for winter. Otherwise you risk some drunk ice fishing fuck breaking into your house.

If someone really wanted to get in, it doesn't really matter what fasteners you use, they would just cut the wood. It just prevents common vandals that happen to have a screwdriver, not determined criminals.

Tamper resistant torx is still a weird niche. Tamper resistant slotted for bathroom stalls makes sense because a person with a coin could disassemble a whole row of stalls without any effort, but if you're carrying around a torx bit, you might as well be carrying around a security bit.

For some reason, Ford decided to use Security Torx to hold together their hybrid battery packs. Couldn't tell you why that was better then regular Torx.

I'd guess that was some sort of safety standard designed to protect vehicle owners from themselves.

As Torx gets more and more common, it's presence is less and less likely to be a serious hurdle, so the security screws are a simple way for them to sort of say to the owner "don't mess with the stuff below this". If they want to, they still can, but it's a specific effort at that point...so Ford can say they've implemented a safety measure. Might even be some sort of government standard too, where using a less common fastener style brings them into compliance without needing some sort of even less accessible design, like a sealed off system.

Who said we are? It's up to Congress to regulate things like that and they don't know shit about fuck. Unless someone "lobbies" them to do it of course.

You can turn a tamper proof screw into a regular screw by using a flat head as a lever and breaking off the center post. Harder to do the bigger the screw is.

The EU should fine companies for introducing new standards that break old standards. Or any shit standards like Toslink: https://lemmy.world/comment/10671314 . Standardization organizations shouldn't be sleeping through all this shit.

I never realised how stupid it is that toslink can only plug in 1 way

I don't use screw drivers enough to know what these are for. But from a programmer's standpoint, punishing people to deviate away from standard may cause more harm than good, no?

Suppose it's easier/cheaper/more effective to deviate a bit from standard, why should I be punished to do things a bit differently?

One issue is that it can be leveraged to maintain a monopoly. Microsoft famously made a bunch of small modifications to the HTML standard, so that web sites that wanted to work with MS Internet Explorer had to write custom versions to be compatible. But because so many people just used IE because it was bundled with Windows, those "extensions" started to become their own standard, so that then other browsers had to adopt MS's idiosyncrasies in order to be compatible with the sites, which in turn harmed standardization itself. They even had a term for this technique: "Embrace, Extend, Extinguish." It nearly worked for them until Google pushed them out with Chrome. Microsoft tried to do the same thing again with Java until the government got involved.

It's complicated, certainly, but there are legitimate cases where "just a little tweak" can be quite a big problem for a standard.

Thanks for the explanation.

Think about all the micro USB, lightning cables, USB cables etc. In programming it's different, but for this stuff it's a waste of money and actual resources.

Why does Torx Plus have six teeth but tamper-resistant Torx Plus has five? Whereas 'what the fuck is this' basically looks like it should be tamper-resistant Torx Plus?

I guess they wanted to make the screws even more tamper-resistant? With the standard Torx Tamper-Resistant screws, they could often be bypassed by chiseling the pin away with a flathead and a hammer, and then using a standard Torx driver. Can't do that with the pentalobular design!

Torx drivers are forward compatible with Torx plus screws

Torx is the 🐐! Phillips are just terrible, I prefer slotted over Phillips. You can slip out quite easily with slotted but if you are in there they work ok.

Phillips are horrible. You need to have 20 different ones that look all the same and you have to try them multiple times to figure out which slip the least. The post and people with no clue make it seem like they make new torx every day to fuck with people. If you have a 15, 20 and 25 torx bit you can use most torx screws out there. If you work on small applications you need a 10 and below. If you use massive screws you ned a 30 and a 40.

+1 for hex, but that's in a lab setting --- climate controlled environment, generally not high torque, pretty benign conditions. But even that is fraught with metric-vs.-imperial mix ups.

The key is to drag the US into the future along with literally everyone but Liberia and Myanmar.

Get a set of rotary broaches in the nearest metric size up from the imperial ones and remove the problem.

Fuck you all!! I’m not arguing about this again :(

But I found this interesting.

https://www.thoughtco.com/history-of-screws-and-screwdrivers-1992422

Plus what?!

Torx++

Not to be confused with Torx#

Unexpected lonesome German

The "wtf is this?" is settings, obviously.

And how many of these are needed by the dictates of their use VS how many are needed to restrict your access?

Why is tamper-resistant torx plus the only one that's 5-pronged?

Apple?

because the goal of tamper resistance is to make it harder to unscrew without apple's approval

To make it even less likely that someone will be able to get it unscrewed without having the right set.

They’re not perfect, obviously, but they do harden a target more than regular Torx.

I use tamper resistant screws to keep an AirTag on my eBike to discourage its removal. Obviously a determined thief could remove it, but lots of stolen bikes get abandoned anyway. My hope is that if it gets stolen it gets abandoned and I can find it then.

Okay, then a slightly different question: why aren't tamper-resistant torx (non-plus) 5-prong?

When you buy the screws they usually come with a drill bit that fits them

АW Drive On Top

Ah, torx plus, used on Chevy bellhousings. Real easy to strip with a regular torx driver.

Reject threaded fasteners, return to nail and rivet.

Y'all need Jesus

^H^H^H^H^H^HRobertson screws.___I hate torx and my superduke is covered in those fucking things